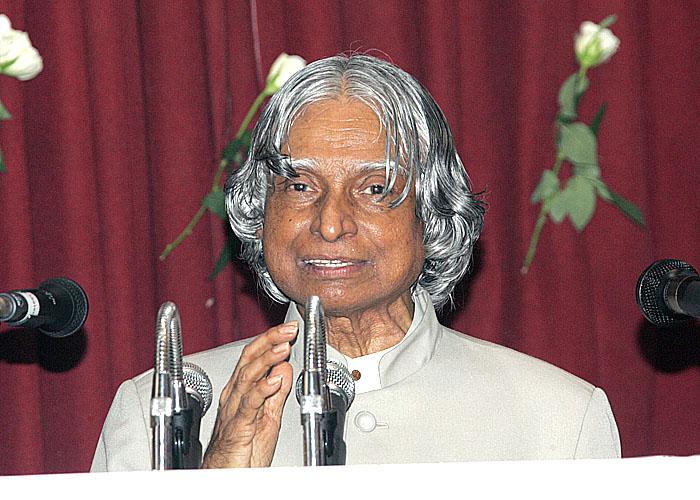

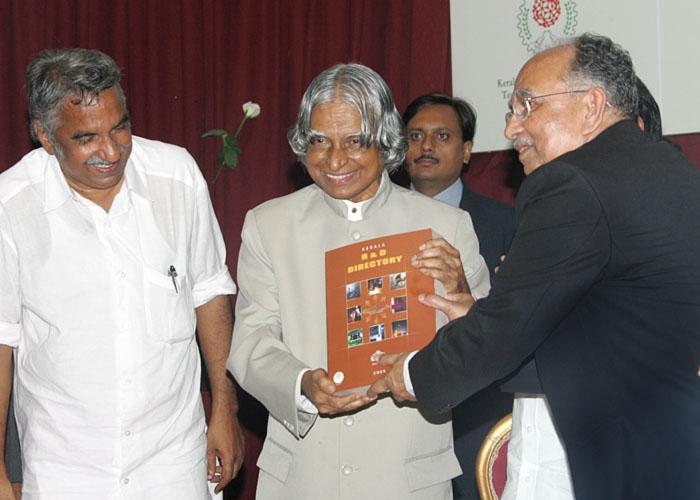

Address at the Symposium and Publication of the Directory of R & D Personnel, Thiruvananthapuram

Thiruvananthapuram : 28-07-2005

Competitiveness through Partnership

I am delighted to participate in the inauguration of the Symposium on Industry R&D Linkage organised by the Kerala Government, Kerala State Industrial Development Corporation educational institutions, R&D Institutions and industrial partners. My greetings to the scientists, technologists, administrators, industrialists, researchers, planners, members of the academia and other distinguished guests. I would like to discuss with you today at this important event on the topic ?Competitiveness through Partnership?. Industrial development needs three aspects : competitiveness, innovation and creative leadership.

Law of Development

I was studying the development patterns and the dynamics of connectivity between nations, especially in trade and business. As you all know the world has a few developed countries and many developing countries. What is the dynamics between them and what connects them? Developed country has to market their products in a competitive way to different countries to remain as developed country. The developing country to get transformed into developed country, they too have to market their products to other countries in a competitive way. Competitiveness is the common factor between both developing and developed countries. It has three dimensions: quality of the product, cost effectiveness and supply in time. Indeed this dynamics of competitiveness in marketing of products by developing and developed countries is called the "law of development".

Innovation

Innovation is the key for competitiveness. In the recent Global Competitiveness Report, I find, in terms of Innovative Capacity Index, US is ranked one, Singapore 6, South Africa 27, China 40, Brazil 42 and India 44. In the same report I noticed that, the proportion of Scientists and Engineers Index is stated as US 4, Singapore 6, South Africa 38, China 43, Brazil 51 and India 60. Thus, we can see the large proportion of new ideas and innovation are generated by scientists and engineers and in the Universities campuses. This innovation arises from private sector initiative and the R & D productivity of the firm, shaped by local policies and nature of local institutions. National innovative capacity has to be the country?s important potential to reinforce both political and economic entity with commercially relevant competitive products. This capacity is distinct from purely scientific or technical achievements and focuses on the economic application of new technology. Thus, for building innovative capacity, we require the partnership of a cluster consisting of public and private sector industry, R & D and academia. I would like to give some examples of successful partnership.

Technology denial management

In the year 1992, Light Combat Aircraft team decided to go for Digital-Fly-by-Wire Control System (FCS) for the Combat Aircraft. At that time, the country did not have the experience in developing FCS. The only two countries who had the experience were France and US. The French company (Dassaut System) had expertise in Hybrid systems whereas our need was an all Digital-Fly-by-Wire. Hence, it was thought appropriate to have a US partner who had the capability in design, development and integration of FCS on fighter aircraft. There were three candidates, General Electric Control that later became LMCS (now called BAe systems), Lear Astronics and Bendix. Finally, we chose LMCS since they had the experience in designing FCS for F-16 Aircraft. Joint Team for design and development of the FCS was formed with ADE (DRDO Lab) and LMCS. The work share between Indian team and LMCS team was identified. Evolution of the SRS was the joint effort. The prototype flight control computer was to be done by ADE. Total system integration was the joint responsibility. Flight certification was to be provided by LMCS.

The contract progressed, though a bit slowly, between 1992-98. Then, as you all are aware, India carried out its nuclear test on 11th May 1998. As soon as this event occurred the American Government imposed technological sanction. Due to the sanction, LMCS broke the contract and retained all the Indian equipment, software and the technical information which were in their premises.

This was definitely a shock for the Indian team. Immediately, I called for a meeting of Directors of ADA, NAL, ADE, CAIR, HAL, National Flight Test Centre, Prof I.G. Sharma, a renowned control system specialist, IISc, Prof T.K. Ghoshal, a noted digital control system expert of Jadavpur University and guidance and control specialists from DRDL and ISRO. The FCS team explained to these members the situation arising out of the unilateral termination of contract by LMCS. We had a full day discussion on the methodology, that needed to be followed, by which we can successfully complete the development of digital fly by wire system and fly the LCA. The team, after prolonged deliberations, gave a structured method by which the development can be completed and the system can be certified for flight trials. They also mentioned that they will support the programme in whatever capacity they have to work with the ADE and ADA teams.

Based on the recommendations of the specialists we immediately strengthened the ADE software team with additional ten experienced software engineers from ADA. ADA was given the responsibility of verification and validation of software. Integrated Flight Control System review committee was constituted with Director ADE as Chairman and Programme Director ADA as Co-chair to support development and resolve all the conflicts arising between Control Law Team, Iron Bird, Software, Hardware and simulation. This team met once in a week and brought out all the issues arising in different work centres and solutions were found. In addition, an Iron Bird review team was formed with Project Director Flight Control System as Chairman with members from HAL, ADA, ADE, certification agency (CEMILAC) and Test Pilots from National Flight Test Centre as Members. This team also met every week and resolved all the problems arising in the development and Test on Iron Bird. We also introduced participation of certification agency (CEMILAC) and inspection agency in all these reviews. The aim was to see that any problem in any system is brought into focus at the earliest so that the solution can be found. In addition, we made it a point to have a special agenda in the monthly technical committee meeting on the development of integrated flight control system wherein Director (ADE), Director (NAL), Director (National Flight Test Centre), General Manager (HAL) presented the progress and problems. The confidence building took place by intensifying the tests. For example, informal Iron Bird test was carried out over thousand hours and the formal Iron Bird test was conducted over hundred and fifty hours. Similarly, Pilot flew the simulator for more than two thousand hours. Thus, what we missed from the foreign partner, we compensated by enhancing the critical design review and increasing the test time to ensure safe man rated design of the integrated flight control system.

The entire team took the denial as a national challenge. They said if it were going to take three years we would do it in two years. If it is going to take twenty million dollars we will do it in ten million dollars. Our working hours was not eight hours. We worked twenty-four hours a day and completed the task. That was the time I realized the power of Indian Scientific Community, the power of Indian industry, the power of the Indian academia and the power of our country. I realized that no country could dominate us by imposing technological sanction or economic sanction. Power of scientific team will defeat the petty designs of any nation. Today I can proudly say that our scientists have designed, developed, tested, evaluated, and integrated the integrated flight control system in the LCA, which has logged more than 400 trouble free flight sorties in three different aircrafts.

ISRO Experiences

In Kerala, VSSC is a good example of how R&D, academia and industry worked in an integrated way to realize from design, development, testing and finally leading to industrial products. For example, when the ammonium perchlorate process was developed in the laboratory in association with academic institutions, it led to the establishment of Ammonium Perchlorate Plant (APEP) with 150 ton capacity. There is provision for further increase. Similarly, the polymers developed by VSSC has led to establishment of industrial production at Thiruvananthapuram and Mumbai. A small lab called FRP was started and it has now been transformed into Reinforced Plastics Centre (REPLACE) at Vattiyurkavu. The REPLACE is supported by a network of industries in the field of composite products through transfer of technology. Another important high-tech production unit in Vattiyurkavu has been established for producing precision inertial systems. Similarly, in Valiamala, ISRO has another establishment called Propulsion Control Systems and Components Production Group for arranging production of precision control components.

You can see, how one single mission from Dr Vikram Sarabhai has spread into multiple R&D Labs, multiple production centres, interfacing with national industries, academia and R&D centres. These examples demonstrates the power of synergy created by R&D, industry and academia linkage. I have given you these examples which will enable you to collectively contribute in the transformation of Kerala into a developed State. For realizing this Creative Leadership is necessary.

Creative Leadership

I would like to discuss the relationship between the economic development, technology and industries and the leadership.

- Nation?s Economic development is powered by competitiveness.

- The competitiveness is powered by knowledge power.

- The knowledge power is powered by Technology and innovation.

- The Technology and innovation is powered by resource investment and partnership between R&D, Academia and industry.

- The Resource investment/partnership is powered by revenue and return on Investment.

- The Revenue is powered by volume and repeat sales through customer loyalty.

- The customer loyalty is powered by Quality and value of products.

- Quality and value of products is powered by Employee Productivity and innovation.

- The Employee Productivity is powered by Employee Loyalty, employee satisfaction and working environment.

- The Working Environment is powered by management stewardship and sound project management.

- Management stewardship is powered by creative leadership.

Who is that creative leader? What are the qualities of a creative leader? The creative leadership is exercising the task to change the traditional role from commander to coach, manager to mentor, from director to delegator and from one who demands respect to one who facilitates self respect. This is particularly important in realizing products through totally native technology.

Conclusion

When I was addressing the Kerala Assembly this morning, I have given 10 missions for prosperity of Kerala. This symposium can discuss those ten missions and evolve a strategy for implementation through networking R&D, academia and industry. If these missions become bigger than individuals and organisations, definitely Kerala will succeed in becoming a developed state, especially because of its core strength of unity of minds, being the number one in the Human Development Index and also with the wealth available from 2.7 million Keralites working in various parts of the world.

Since the Hon?ble Governor, the Hon?ble Chief Minister and the Hon?ble Minister for Industries are here, I would like to suggest that Kerala must create an investment friendly environment for industrial development and for growth. This will enable creation of enterprises, employment potential and poverty alleviation. God is with you in this mission.

I hereby inaugurate the symposium and my best wishes to all the participants for success in their deliberations.