Address at the 25th Convocation of National Institute of Design, Paldi Ahmedabad

Ahmedabad : 05-01-2005

Competitiveness through Design

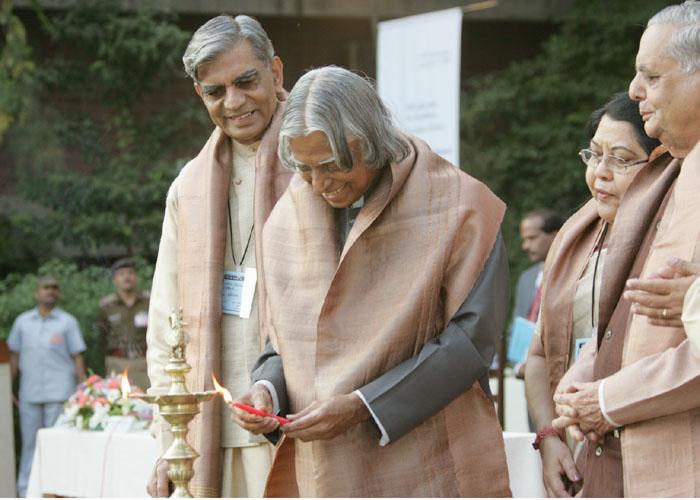

I am delighted to participate in the 25th Convocation of the National Institute of Design, Ahmedabad which is a multi disciplinary institution in the field of design education, applied research, training, design consultancy services and out reach programmes. My greetings to the Chairman and members of the NID Governing Council, Executive Director, Faculty Members, researchers, students and distinguished guests. My congratulations to the Graduates and Post Graduates for their excellent academic performance.

Design interprets culture. Culture creates values and values shape the future with competitive marketing. The Faculty Members of this institute have been propagating this phenomena of design among the students and preparing their minds for creating a good future for themselves and the industry to which they become a part. This I would consider a significant human resource development providing value addition to our native products and they deserve recognition and commendation. Competitiveness is the key for transforming India into a developed nation. Now I would like to discuss the Law of Development and competitiveness.

Law of development

I was studying the development patterns and the dynamics of connectivity between nations, especially in trade and business. As you all know the world has few developed countries and many developing countries. What is the dynamics between them and what connects them? Developed country has to market their products in a competitive way to different countries to remain as developed country. The developing country to get transformed into developed country; they too have to market their products to other countries in a competitive way. Competitiveness has three dimensions: quality of the product, cost effectiveness and supply in time. Indeed this dynamics of competitiveness in marketing of products by developing and developed countries is called the law of development. The students of the National Institute of Design have a very important role to play in improving the quality of the product by injecting aesthetics, user friendliness, promoting cost reduction techniques through the use of locally available raw material and creating designs using existing processes.

Thrust for indigenous technology

Technology is a non-linear tool that can effect the most fundamental change in the ground rules of economic competitiveness.

Technology consists of stages like research and development, technology transfer, technology absorption, and production of products or systems with the desired performance, quality, and cost-effectiveness. Technology development can be achieved through two routes?Route A and Route B. Route A (know-how) involves obtaining licensed technology or techniques including manufacturing, design drawings, and production processes from an established manufacturer from abroad.

Route B (know-why) begins with designing and developing indigenous technology. In the case of India, progress in technology, particularly indigenous design, is the thrust area to enable India to become competitive with other countries. To be competitive within India and in the global market, it is essential to evolve a value-chain in a product life cycle. Value-chain is provided for the wealth generation and quality improvement in percentages. In any product among specifications/requirement, design, process, manufacturing, services, and product improvement, wealth generation depends largely on the design strength, which is 60% of the product life cycle effort. It is also evident that the quality has to be built-in at an optimal level during the design phase itself (quantitatively about 40%). For a product value-chain, largely design effort with built-in quality influences the competitiveness of the product.

Based on the experiences gained in launch vehicles and guided missiles, India has the competitive edge to design and develop any type of launch vehicle, missile, military aircraft and reusable systems. With the partnership of Indian academic institutions, industry and different R&D departments, we can definitely see the tremendous strength India has in critical sectors. The enthuseour younger generation must understand India's capability to carry out complex aerospace designs with an integrated approach. This also establishes that India has the capability for systems design, systems engineering and systems integration of rockets, missiles and launch vehicles. This capability has provided the necessary impetus for the production and marketing of aerospace systems to the customers delight.

Indigenous design and development capabilities are the keys to gaining a competitive edge. The competitive edge is governed by low-cost, high quality and superior performance, and timeliness that will bring customers delight which is a function of design and development, manufacturing and service.

The nation?s strength in the design and development of high technology products and product engineering will also increase exports. It is therefore important that the Indian R&D sector, design centres, and industries recognise this dimension of technology.

Computer integrated manufacturing

We have made the leap from CAM to design integrated manufacturing for aerospace systems and automobiles. Virtual Reality (VR) simulations have also evolved. The additional feature now is a new software that provides immersive visualisation of a 3-D environment. This technology has been used for walk-throughs in LCA prototypes which is saving 40% of the design time in the LCA undercarriage assembly and environmental control system bay. Similar VR models have been used in designing the Indica car of Tata Engineering. Rapid prototyping technologies (or free form fabrication) can build up complex 3-D parts direct from CAD input without any other machinery.

CIM is the automated version of the manufacturing process where the three major manufacturing functions? product and process design, planning and control, and the manufacturing process itself?are integrated by the automated technologies described above. Further, the traditional integration mechanism of oral and written communication is replaced by computer technology. Such highly automated and integrated manufacturing is also, called the ?Factory of the Future?. The Heavy Alloy Penetration Plant (HAPP) in Tiruchirapalli established by DRDO for Ordnance Factory is an example where this concept has been applied for manufacture of FSAPDS (Fin Stabilised Armour Piercing Discading Sabot). Established in 1988, this factory has led to tight tolerances consistency and repeatability in production, lower rejection rates, and large production volumes. What would have normally required 600 workers is being carried out faster and to the required quality with an 80 member team.

Product value addition

India has to work hard in value addition techniques in its manufacturing industries, in honing the core competency of skilled manpower, in procuring raw materials, and in upgrading capital equipment.

We must create a sound environment to help the manufacturing sector cope with the emerging challenges of globalisation. This could include the following measures:

- Special thrust on modernisation and technology upgradation of existing units

- Special package for promotion and development of small and village enterprises

- Consortium of Indian R&D laboratories and industries to gain design development that will enhance competitiveness

- Technology support

- Marketing support

- Credit support

- Entrepreneurship development

- Promotion of self-employment

- Infrastructure

- Facilitation

NID is an important institution which has already interacted with multiple R&D organizations such as DRDO, ISRO, ADA and industries to enable product engineering of the prototypes. This contribution has enhanced the value of the product and increased the competitiveness. With this background, I would like to discuss one example of my experience with NID.

My experience with National Institute of Design

Aeronautical Development Agency (ADA) a DRDO establishment has developed a technology for Maintenance Training Simulator (MTS) for improving the quality of maintenance of Air Force equipment which has been granted a product patent. When the first aircraft system maintenance simulator was built for MIG 29 aircrafts by ADA and evaluated by the Air Force they gave the following comments:

(a) They related it to a personal computer instead of high tech simulator due to the product look.

(b) Visual displays required improvement for better cognition.

(c) Equipment needed better user friendliness.

(d) Facility required for importing visuals developed using imported software packages.

To meet the requirements of the Air Force, ADA approached National Institute of Design (NID) for getting design support in view of their excellence in industrial and communication design. NID team headed by Dr. S. Ghoshal, Centre Head, NID Bangalore Centre supported by diploma students redesigned the simulator utility panel to repackage the equipments of Aircraft System Maintenance Simulator (ASMS). ADA and NID team also gave ergonomic improvement to visual representation. I understand that the designers of NID followed a design intervention techniques which involved:

* Assimilation of task brief & research

* User studies & requirement analysis

* Planning & ideation of design concepts

* Product visualization & design concept development

* Value engineering & design freeze

* Material analysis & selection

* Design validation through prototyping

* Manufacturing drawing release & prototype fabrication

* Production drawing freeze

With this approach ADA was able to deliver a domain free ASMS to Air Force Technical College, which is now being extensively used and has been found to meet all the requirements of ab-initio training of aeronautical engineers on combat aircraft system. With this background the Air Force asked ADA to develop multiple types of training systems and maintenance simulator for MIG 21 BIS upgrade aircraft requirements. The intervention of NID has resulted in producing simulators which has a high level of acceptability by the user. Looking at the professionalism of product, potential users are asking ADA to develop and deliver multiple products to meet their training requirements.

As you are aware the rural development programme of our country is through the creation of PURA (Providing Urban Amenities in Rural Areas) in our village clusters. This area is a fertile ground for creating small scale, cottage and artisan based industries based on our native knowledge. The designers of National Institute of Design can make an important contribution in developing products for enterprises based on traditional knowledge. Hence I would like to discuss the concept of PURA.

PURA (Providing Urban Amenities in Rural Areas)

Nearly 700 million people of India live in the rural areas in 600,000 villages. Connectivity of village complexes providing economic opportunities to all segments of people is an urgent need to bridge the rural-urban divide, generate employment and enhance rural prosperity. The essential needs of the villages today are water, power, road, sanitation, and healthcare, education and employment generation.

Essential Connectivities through PURA: The integrated methods, which will bring prosperity to rural India are: the physical connectivity of the village clusters through quality roads and transport; electronic connectivity through tele-communication with high bandwidth fiber optic cables reaching the rural areas from urban cities and through internet kiosks; knowledge connectivity through education, vocational training for farmers, artisans and craftsmen and entrepreneurship programmes; these three connectivities will lead to economic connectivity through starting of enterprises with the help of banks, micro credits and marketing the products.

When the PURA enterprises emerge one of the very important requirement is employment generation. In a cluster of villages there may be many types of competencies like artistic work, cottage products and small scale industrial products. Most of the time our products may not be competitive in the international market. Therefore, it is essential that our products should have a new look and production capability in large number with technology addition through the design intervention of NID designers.

Now I would like to discuss some of the products where design and computer aided design intervention has provided a new thrust to some of our rural products.

Kancheepuram Story

The silk industry in Kancheepuram is one of the fastest growing industries in India. The industry currently employs more than 30,000 weavers in the art of saree making. The industry had to compete with the synthetic fiber industry in many aspects. The industry was on the brink of extinction due to the obsolescence of the designs and design making procedures. This is because, design adds splendor to a saree and forms an integral part of its exquisiteness. This may be true with many handloom saree producers in different parts of the country. Introduction of computerized Jacquard border design in Kancheepuram silk saree has helped in the revival of the industry. The use of Computer Aided Design has not only helped in creating new and complex designs but also reduced the time involved in the design. There has been an increase in the exports. The acceptance of these silk sarees by the consumers has also increased with the automation of designing process. Visualization of saree designs ahead of its production and the ability to create new color combination at the click of a mouse has increased the flexibility and reduced the time for realizing new designs. Though the materials and the techniques are changing with the market demand, the motifs are still conventional to hold the custom and tradition of the Kancheepuram saree. The silk industry in Kancheepuram has transformed into a high growth industry by opening up new avenues for the traditional weavers. The example illustrates that computer aided design can help renewal of a traditional industry provided the new technology is simple to use and users are trained properly which is compatible with the traditional manufacturing process.

Leather industry

Leather industry is a traditional industry. Kolhapuri is a traditional chappal manufactured through a manual process. This is a case study of the manner in which the design process, manufacturing process and marketing was reengineered using CAD interventions. Use of Computer Aided Design helped this industry to reposition itself. The main reason for the early adoption and rapid diffusion of the new technology has been the systematic training carried out by Central Leather Research Institute (CLRI) for imparting skills in the local craftsman using two people from the same trades. The income of craftsman increased considerably after the adoption of CAD for designing and market access. The production increased from about 20 pairs per week to almost 200 pairs per week. CLRI also helped in changing the manufacturing process such that the productivity has gone up apart from the use of computer aided design. The designs have shown a quantum jump both in terms of quality and variety. The whole project was implemented under the National Leather Technology Mission. An NGO from Bangalore helped in selling the Chappals on line thereby enhancing the price realization. The exports have shown an increase. On the whole this is an exciting experience of using new technology to reengineer and renew a traditional industry. The main reason for the success has been the training of the local craftsman by CLRI.

These two experiences clearly indicate the success components of such missions. They are application of Computer Aided Design, partnership with the R&D and entrepreneurs; value added training to the crafts men and marketing support. Graduates and Post-graduates of National Institute of Design should work towards replicating this model in different parts of the country. State and Central Government should proactively facilitate nurturing of the industry.

Design for Disaster proofing

India has various forms of disasters landslide, earthquake, floods, cyclone and tsunami. Why not generate designs of location specific options of habitats of various types and sections of people so that loss of lives is reduced. Also of options of designs for structures in sea coast which can minimize deaths and property loss.

There are yet unconfirmed reports that the tribal population and animals including cattle were not affected by the Tsunami as much as the other population.

We must work towards learning the right lessons even from this disaster so that our future can be safe. The fishermen of late seem to have been pushed to live more closer to the sea shore than ever before due to the demands placed by tourism and urban development. I strongly feel that this trend should be reversed and the law that human habitats should be atleast 500 Meters away from the sea should be strictly enforced.

Inspite of various precautions disasters and accidents happen. Often we do not handle crisis systematically. For example there are high rise shelters in areas, often prone to floods or cyclonic rise for people to stay for a few days till floods recede. Even fast evacuation system can have designs without stampede which cause death. World over designers apply their mind to these practical issues?

Traditional Craftsmen Capability

During my visit to the North Eastern States particularly to Arunachal Pradesh and Nagaland, I found in every village even every house has a unique pattern of life. They hand weave their dresses and dye it themselves with beautiful colours. They make their own headgears. A design organisation like yours can visit and study this traditional craftsmanship capability and hand weaving capability for further augmentation through technology and design, so that, we can enrich the people of Arunachal Pradesh and Nagaland.

Conclusion: Creative Leadership

There are 540 million youth below 25 years in the population of a billion people. The nation needs young leaders who can command the change for transformation of India into a developed nation embedded with knowledge society. . The leaders are the creators of new organizations of excellence. Quality leaders are like magnets that will attract the best of persons to build the team for the organization and give inspiring leadership even during failures of missions as they are not afraid of risks. I have seen and worked with creators of vision and missions.

One of the very important ingredients for success of the vision of transforming India into a developed nation by 2020 is the evolution of creative leaders. I am giving a connectivity between developed India, economic prosperity, technology, production, productivity, employee role and management quality, all of which linked to the creative leader. Who is that creative leader? What are the qualities of a creative leader? The creative leadership is exercising the task to change the traditional role from commander to coach, manager to mentor, from director to delegator and from one who demands respect to one who facilitate self respect. The higher the proportion of creative leaders in a nation, the higher the potential of success of visions likedeveloped India.

Mission of National Institute of Design is the creation of creative leaders who will be participating in the transformation of India into a prosperous, happy and strong nation. I wish all the graduates and post-graduates a very bright future and I am sure you will make India's second vision a reality through your creative skills.

May God bless you.