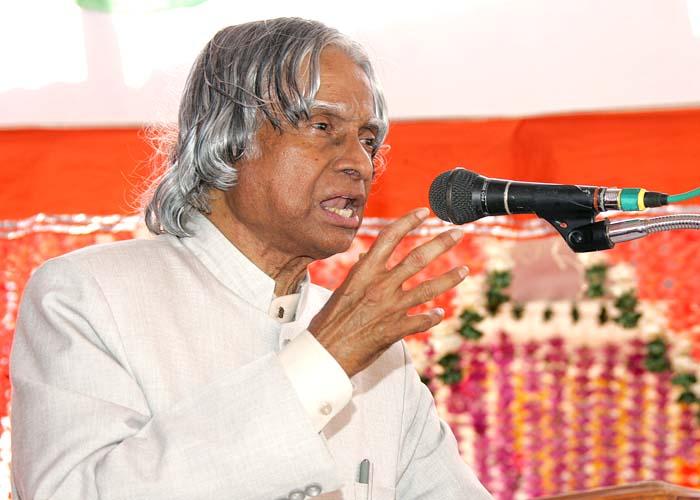

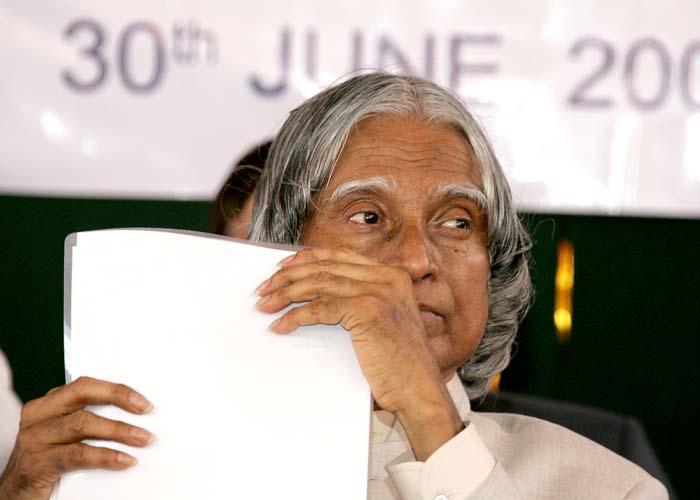

Address at the Floor Reaction Orthosis (Fro) Camp

Akkaraipettai : 30-06-2005

Godly Children

I am delighted to participate in this function organized by the DRDO in collaboration with Nizam Institute of Medical Sciences, Hyderabad and Sastra University. I am happy to be among the children particularly special children who have been fitted with light weight calipers. The future of any nation depends on children and youth, and their well-being is of utmost important. Assisting polio affected children with Floor Reaction Orthosis (FRO), a spin off product of Defence Technology is a noble task. When I am here, an incident comes to my mind.

Once, I was addressing the students at Mount Abu in Rajasthan. A girl among the students asked me a question that out of many achievements which one gave me the maximum happiness. I replied her that "When SLV-3 injected Satellite in low earth orbit, it was a happy moment for me because India entered into the elite space club of select countries. Thereafter, when Agni reached the target point, the country reached the capability of having IRBM it gave me happiness. Later came the nuclear experiment at Pokhran and the country became nuclear weapon state, it was another moment of happiness. When the TIFAC team submitted to Government the Technology Vision of 2020 for Developed India, it gave me more happiness. When I see smiling faces of children fitted with light weight callipers, a spin-off product of defence technologies and the tears of joy roll-out from the parents of those children, it gave me Bliss." Today I am getting the Bliss again, on seeing all of you.

FRO Technology

FRO, Floor Reaction Orthosis is a walking aid for the polio affected children. Its conventional version was introduced in India by Prof. PK Sethi of Jaipur and Prof SC Lakkad of IIT, Bombay, way back in 1983. Then in the early 1990s, the doctors from Nizam?s Institute of Medical Sciences, (NIMS), Hyderabad contacted me and asked how the high technologies of defence can be used for medical science. They brought out the specific problem of polio appliances, which are required in great numbers and conventional method, of their fabrication, will not be able to cater the need of the country. Moreover, they felt that there was a need to improve upon the materials and quality. Immediately, I thought of advanced composite materials, used in the fabrication of missile airframes, which are quite light weight and very strong. I thought that why do I not use them for the fabrication of light weight, ultra strong and durable standardized walking aids. The standardization was the only way to mass produce these walking aids in order to cater the needy children. Then, a team consisting of scientists from DRDO and doctors from NIMS was detailed to study the problem and later a project was sanctioned jointly by Department of Science and Technology and Ministry of Social Justice and Empowerment.

Standardisation

The project team consisted of doctors, orthotists, plastic engineers, mechanical engineers and software engineers. An equipment namely Anthropometric Measuring Device, for generating data on polio affected lower limb, was invented and data on more than 1000 polio affected limbs were generated through various polio camps all over the country. These data were analyzed by specially developed software programme namely ?FROSTAN?. After the analysis, modular concept with standard sizes was evolved leading to three modules namely foot piece, knee piece and pair of lateral uprights. The materials chosen for the fabrication for these modules were E-glass reinforced polypropylene composites and these modules were productionised trough injection moulding and compression moulding technologies. For the initial phase of the production and trials, the local industries at Hyderabad participated. The trial fitment was carried out on over 500 polio affected children at various parts of India. The response of the children fitted was overwhelming and feedback obtained was heartening. The doctors and orthotists were delighted to have a polio appliance which met all their expectations in terms of quality, affordability, light weight and durability.

The standardisation of sizes and use of sate-of-the-art materials and technologies made FRO a high quality and cost effective walking aid which met the expectations of the needy children, doctors and orthotists. The complete technology was transfered to M/s. ALIMCO, Kanpur for the mass production. Presently, ALIMCO is mass producing it and this appliance has been taken to abroad too, by ALIMCO. Presently, FRO is available for Rs.300/- and weighs as less as 300 gm. It can be fitted to a needy child in less than an hour.

Nodal Hospitals

Seven nodal centres have been setup in various parts of the country and people were trained on the diagnosis, fitment and follow-up. These nodal centres are located zone wise all over the country. These nodal centres directly fit these appliances to the needy children and also coordinate with various health centres such as primary health centres, district hospitals, medical colleges, etc. for the fitment of such appliances. Later, NIMS doctors and orthotist came out with innovation idea to use FRO component along with knee joint for long leg calipers. Therefore, long leg caliper became comparatively lighter in weight. Next step towards this development is to re-design the light weight, cost effective and durable knee joints for long leg caliper. This appliance will cover broader spectrum of polio affected children.

Production

So far, more than 7000 such appliances have been fitted to the needy children all over the country. I can see that the FRO technology has reached a mature stage. I am really touched by their movement and actions after the fitment of the calipers. This programme of fitment of FRO and light weight walking aids is a good example of team effort. Such rehabilitation programmes will bring the polio affected children into the main stream of life for enabling them to contribute towards national development task. Other societal application products for relieving the pain of the people have also been developed and produced by our defence scientists.

I wish you all the best. May God bless you.